The HPR 130XD delivers incomparable HyDefinition cut quality at half the operating costs

Hypertherm has spent more than four decades developing over 75 patented plasma technologies to provide customers with exceptional performance they can count on. With thousands of HyPerformance Plasma systems sold around the world, the HPR product family has become the plasma system of choice for customers who demand the most consistent cut quality, highest productivity, lowest operating cost and unmatched reliability.

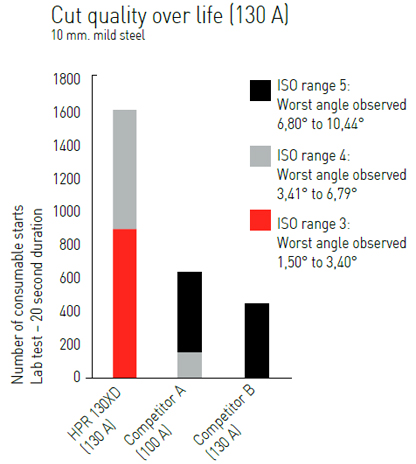

Superior cut quality and consistency

HyPerformance Plasma cuts fine-feature parts with superior quality and consistency,eliminating the costof secondary operations. Patented HyDefinition® technology aligns and focuses the plasma arc for more powerful precision cutting up to 38 mm Patented system technologies deliver more consistent cut quality over a longer period of time than other systems available on the market.

Maximized productivity

HyPerformance Plasma combines fast cutting speeds, rapid process cycling, quick changeovers and high reliability to maximize productivity.

Minimized operating cost

HyPerformance Plasma lowers operating cost and improves profitability. Patented LongLife® technology significantly increases consumable life and enables consistent HyDefinition cut quality over the longest period of time.

Unmatched reliability

Extensive testing, backed by more than four decades of experience, guarantees theHypertherm quality you can count on.

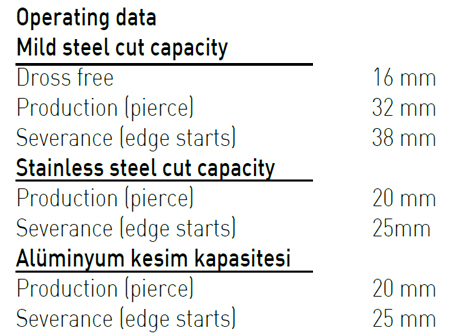

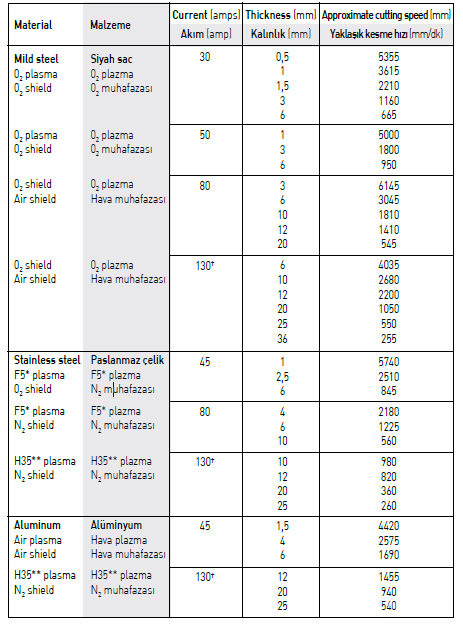

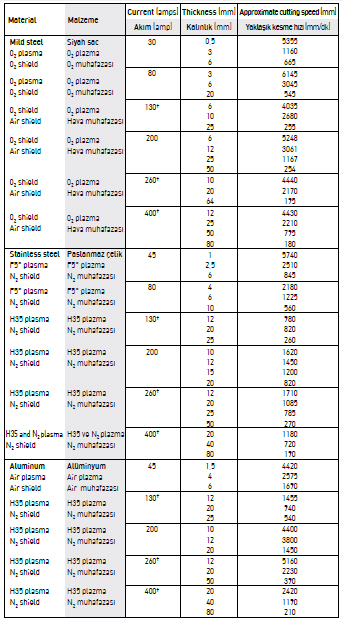

Operating data

Virtually dross-free cutting capacity – mild steel - 16 mm

Production pierce capacity – mild steel - 32 mm

Maximum cutting capacity (edge start) – mild steel - 38 mm

Note:

Take care in comparison: Competitors often show maximum cutting speeds, ratherthan speeds that deliver the bestcuts, as shown above. Cut speeds listed above deliver best cut quality, but cut speeds can be up to 50% faster. The operating data chart does not list all processes available for the HPR130XD. Please contact Hypertherm for more information.

† Consumables support up to 45° bevel capability.

The HPR 260XD delivers incomparable HyDefinition cut quality at half the operating costs

Hypertherm has spent more than four decades developing over 75 patented plasma technologies to provide customers with exceptional performance they can count on. With thousands of HyPerformance Plasma systems sold around the world, the HPR product family has become the plasma system of choice for customers who demand the most consistent cut quality, highest productivity, lowest operating cost and unmatched reliability.

Superior cut quality and consistency

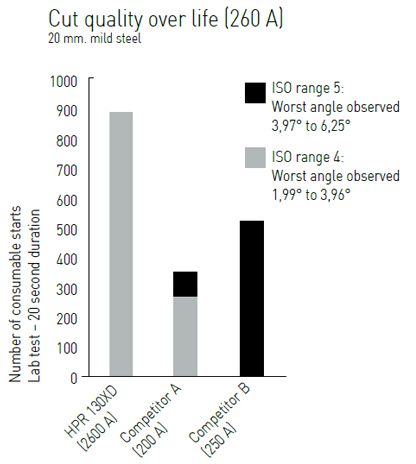

HyPerformance Plasma cuts fine-feature parts with superior quality and consistency,eliminating the cost of secondary operations. Patented HyDefinition® technology aligns and focuses the plasma arc for more powerful precision cutting up to 38 mm Patented system technologies deliver more consistent cut quality over a longer period of time than other systems available on the market.

Maximized productivity

HyPerformance Plasma combines fast cutting speeds, rapid process cycling, quick changeovers and high reliability to maximize productivity.

Minimized operating cost

HyPerformance Plasma lowers operating cost and improves profitability. Patented LongLife® technology significantly increases consumable life and enables consistent HyDefinition cut quality over the longest period of time.

Unmatched reliability

Extensive testing, backed by more than four decades of experience, guarantees theHypertherm quality you can count on.

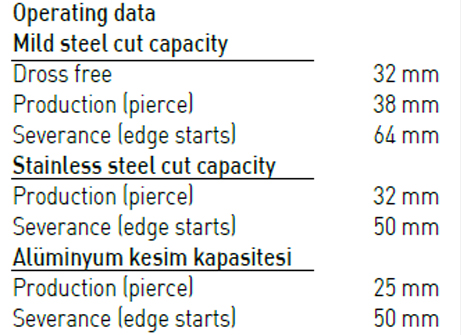

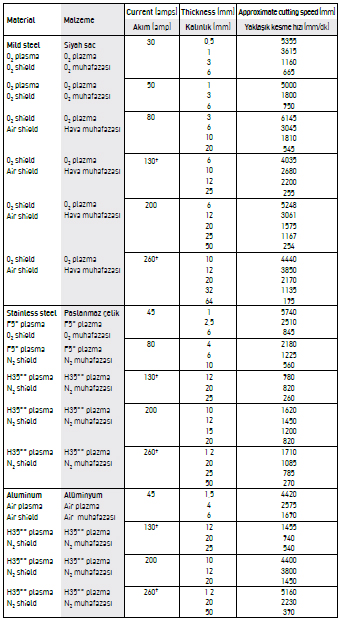

Operating data

Virtually dross-free cutting capacity – mild steel - 16 mm

Production pierce capacity – mild steel - 32 mm

Maximum cutting capacity (edge start) – mild steel - 38 mm

Note:

Take care in comparison: Competitors often show maximum cutting speeds, ratherthan speeds that deliver the bestcuts, as shown above. Cut speeds listed above deliver best cut quality, but cut speeds can be up to 50% faster.

The operating data chart does not list all processes available for the HPR130XD. Please contact Hypertherm for more information.

† Consumables support up to 45° bevel capability.

The HPR 400XD delivers incomparable HyDefinition cut quality at half the operating costs

Hypertherm has spent more than four decades developing over 75 patented plasma technologies to provide customers with exceptional performance they can count on. With thousands of HyPerformance Plasma systems sold around the world, the HPR product family has become the plasma system of choice for customers who demand the most consistent cut quality, highest productivity, lowest operating cost and unmatched reliability.

Superior cut quality and consistency

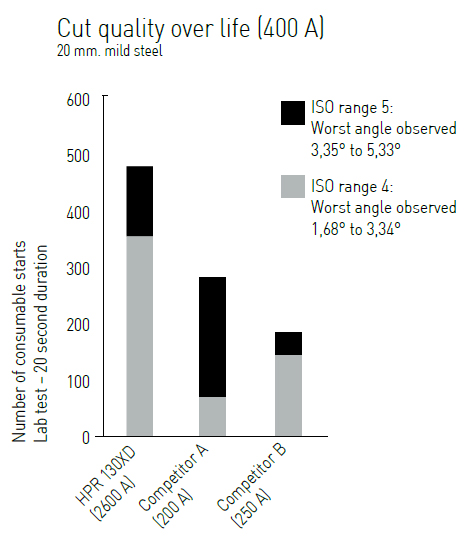

HyPerformance Plasma cuts fine-feature parts with superior quality and consistency, eliminating the costof secondary operations. Patented HyDefinition® technology aligns and focuses the plasma arc for more powerful precision cutting up to 38 mm Patented system technologies deliver more consistent cut quality over a longer period of time than other systems available on the market.

Maximized productivity

HyPerformance Plasma combines fast cutting speeds, rapid process cycling, quick changeovers and high reliability to maximize productivity.

Minimized operating cost

HyPerformance Plasma lowers operating cost and improves profitability. Patented LongLife® technology significantly increases consumable life and enables consistent HyDefinition cut quality over the longest period of time.

Unmatched reliability

Extensive testing, backed by more than four decades of experience, guarantees theHypertherm quality you can count on.

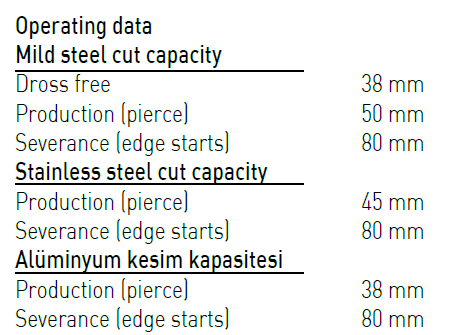

Operating data

Virtually dross-free cutting capacity – mild steel - 16 mm

Production pierce capacity – mild steel - 32 mm

Maximum cutting capacity (edge start) – mild steel - 38 mm

Note:

Take care in comparison: Competitors often show maximum cutting speeds, ratherthan speeds that deliver the bestcuts, as shown above. Cut speeds listed above deliver best cut quality, but cut speeds can be up to 50% faster.

The operating data chart does not list all processes available for the HPR130XD. Please contact Hypertherm for more information.

† Consumables support up to 45° bevel capability.